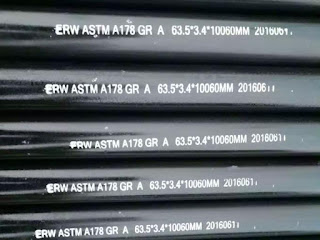

ASTM A178 / ASME SA178 ELETRIC RESISTANCE WELDED CARBON STEEL BOILER TUBES (ASTMA178 / ASME SA 178/ASTMA178/ASMESA178)

Surface Condition:

Finished tubes shall be free of scale,A slight amount of oxidation will not be considered as scale.

This standard is issued

under the fixed designation A 178/A 178M; the number immediately following the

designation indicates the year of original adoption or, in the case of revision,

the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon ( ュ) indicates an editorial change since the

last revision or reapproval.

This specification has

been approved for use by agencies of the Department of Defense. Consult the DoD

Index of Specifications and Standards for specific year of issue which has been

adopted by the Department of Defense.

Scope

1.1 This specification

covers minimum-wall-thickness, electric-resistance-welded tubes made of carbon

steel and carbon-manganese steel intended for use as boiler tubes, boiler flues,

superheater flues, and safe ends.

NOTE 1 Α Type Cand D

tubes are not suitable for safe-ending for forge welding.

1.2 The tubing sizes and

thicknesses usually furnished to this specification are 1/2 to 5 in. [12.7 to

127 mm] in outside diameter and 0.035 to 0.320 in. [0.9 to 8.1 mm], inclusive,

in minimum wall thickness. Tubing having other dimensions may be furnished,

provided such tubes comply with all other requirements of this

specification.

1.3 Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm[ in inside diameter or 0.015 in. [0.4 mm] in thickness.

1.4 When these products are to be used in applications conforming to ISO Recommendations for Boiler Construction the requirements of this Specification A 520 shall supplement and supersede the requirements of this specification.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. W within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must b used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specified in the order.

1.3 Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm[ in inside diameter or 0.015 in. [0.4 mm] in thickness.

1.4 When these products are to be used in applications conforming to ISO Recommendations for Boiler Construction the requirements of this Specification A 520 shall supplement and supersede the requirements of this specification.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. W within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must b used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specified in the order.

Chemical Composition:

Element

|

Grade A

|

Grade C

|

Grade D

|

Low carbon steel

|

Medium carbon steel

|

Manganess steel

| |

C%

|

0.06-0.18

|

0.35Max

|

0.27Max

|

Mn%

|

0.27-0.63

|

0.80Max

|

1.00-1.50

|

P%

|

0.035

|

0.035

|

0.030

|

S%

|

0.035

|

0.035

|

0.015

|

Si%

|

.....

|

.....

|

0.10Min

|

Mechanical Propertise:

Grade A

|

Grade C

|

Grade D

| |

Tensile Strength loading Ksi (Mpa)

|

=47(325)

|

60(415)

|

70(485)

|

Yield Strength Loading Ksi(Mpa)

|

=26(180)

|

37(255)

|

40(275)

|

Elongation (50mm)%

|

=35

|

=30

|

=30

|

Referenced Documents:

ASTM standards:

A450/A450M Specification for General Requirements for Carbon,Ferritic Alloy,and Austenitic Alloy steel tubes.

E213 Practice for Ultrasonic Examination of Metal pipe and tubing.

E273 Practice for Ultrasonic Examination of Longitudinal Welded Pipe and Tubing.

ASTM standards:

A450/A450M Specification for General Requirements for Carbon,Ferritic Alloy,and Austenitic Alloy steel tubes.

E213 Practice for Ultrasonic Examination of Metal pipe and tubing.

E273 Practice for Ultrasonic Examination of Longitudinal Welded Pipe and Tubing.

Manufacturing Process:ERW

Heat treatment:

After welding,all tubes shall be heat treated at a temperature of 1650°F(900?) or higher and followed by cooling in air or in the cooling chamber of a controlled-atmosphere furnace,Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F(650?)or higher.

After welding,all tubes shall be heat treated at a temperature of 1650°F(900?) or higher and followed by cooling in air or in the cooling chamber of a controlled-atmosphere furnace,Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F(650?)or higher.

Surface Condition:

Finished tubes shall be free of scale,A slight amount of oxidation will not be considered as scale.

Mechanical Tests Required:

- Flattenting Test

- Flaring test

- Flange test

- Crush test

- Tension test

- Reverse Flattening test

- Hydrostatic or Nondestructive Electric Test

Material Comparison

Tables (ASTM ℃KS, JIS, DIN, BS, NBN, NF, UNI)

|

ASTM

STANDARD |

UNS

NO.

|

KOREA/JAPANES

|

GERMAN

|

BRITISH

|

BELGIAN

|

FRENCH

|

ITALIAN

| |||||||||||||

|

KS/JIS

Symbol

|

KS/JIS

Numbe

|

Remarks

|

DIN

Type

|

DIN

Number |

Materiral

Number |

Remarks

|

B.S

Number |

B.S

Grade

|

NBN

Type

|

NBN

Grade

|

Remarks

|

AFNOR

Type

|

NF

Number

|

Ramarks

|

UNI

Type

|

UNI

Number

|

Ramarks | |||

|

A 178 C-Steel Electric-Resistance-Welded Boiler Tubes |

||||||||||||||||||||

| Graade A | K01200 | STBH 340 / STB 35 | D3563 / G3461 | St 37.8 | 17177 | 1.0315 | (7) | 3059 | ERW 320 | (3) | (3) | |||||||||

| Grade c | K03503 | SHBH 410 / STB 42 | D3563 / G3461 | St 42.8 | 17177 | 1.0498 | (7) | (3) | (3) | |||||||||||